'UC Factory Lab': University of Coimbra's industrial simulator for engineering education in Portugal

The new Lab is a unique, innovative space in Portuguese higher education.

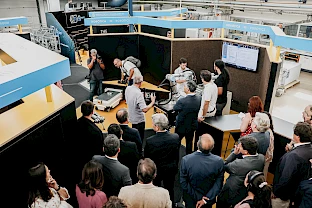

From left to right: Cristóvão Silva, head of the UC Factory Lab project. Cristóvão Silva; Fernando Alexandre, Minister of Education, Science and Innovation; and Amílcar Falcão, Rector of the University of Coimbra.

© Felippe Vaz

The Minister of Education, Science, and Innovation, Fernando Alexandre, congratulated the University of Coimbra on the inauguration of the UC Factory Lab today, the 5ht of July: "The University of Coimbra stands out as a good example of the use of PRR funds to transform our economy and improve our society."

He also stressed that "investments like this are fundamental. Laboratory practice is increasingly important because it brings teaching and learning closer to the needs of the economy, in other words, to the reality of companies," adding, "I'm sure students will have a very innovative, exciting learning experience that will lead to greater success and well-being."

"The UC Factory Lab stands for engineering students in the same way that hospitals stand for medicine and pharmacy students," said the Rector of the University of Coimbra (UC), Amílcar Falcão, highlighting the importance of this new space for teaching in the various fields of Engineering.

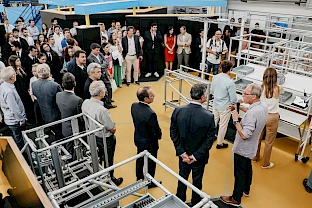

The new space is a unique, innovative space in Portuguese higher education, designed as a learning factory that replicates the industrial environment and can be adapted to different sectors. It aims to provide practical training to university students, secondary school students and companies, focusing on emerging industrial resources such as digitalisation, automation, advanced robotics, augmented reality, virtual reality, artificial intelligence, big data and the Internet of Things (IoT).

The 300-square-metre facility is the first of its kind in the country and results from a €900,000 investment funded by the Recovery and Resilience Plan (PRR). The UC Factory Lab has been designed according to the Learning Factory concept, which replicates an industrial environment that can be adapted to different sectors, from nanopharmaceuticals to the automotive industry, from steel to oil refineries, among others.

By providing a teaching environment similar to a 'real' industrial unit, Learning Factories aim to reduce the gap between theory and practice, preparing future engineers for their everyday lives.

"We will move from the classroom to the factory, where students can practice what they learn in the classroom in a factory environment without having to go to a real factory," said Cristóvão Silva, head of the UC Factory Lab project. The facility will also be used for short courses for companies that want to provide lifelong training for their senior managers.

In the UC Factory Lab, participants can experience the production process firsthand, evaluating, deciding, and intervening in unexpected situations, just like in a factory. For example, they will need to know how to respond to operational challenges and apply problem-solving strategies through experimentation in a controlled environment.

By providing a teaching environment similar to a 'real' industrial unit, Learning Factories aim to reduce the gap between theory and practice, preparing future engineers for their everyday lives. To this end, the UC Factory Lab was designed around three main areas: robotics, virtual control and augmented reality, and production cells and intralogistics.

The robotics area provides training in a range of skills using four types of equipment: mobile robots, mobile collaborative manipulators, collaborative manipulators, and quadruped robotic assistants. These robots are equipped with advanced sensors such as cameras and force sensors to interact with the environment and make real-time decisions.

Industrial processes are simulated, and full-scale production processes are virtually controlled in the Virtual Control Room (VCR) and the Virtual Reality Room (VRR). The Virtual Reality Room provides an immersive environment where trainees can visualize and interact with the production environment realistically and interactively.

Specific production tasks are performed in production cells, autonomous and flexible units combining equipment, robots and operators. These cells are modular in design and can be adapted to different training needs. Intralogistics includes systems to transport, store and move materials within a production environment using robots and warehouse management systems.

With these resources, students and teachers will be able to work with the robots and test the application of concepts and methods to optimise production processes.

The UC Factory Lab will welcome students from the University of Coimbra and secondary schools, and it can also be used as a training platform for professionals in the business world. Masters and PhD students will also be able to do research and development on new processes and equipment in this new space.